By facilitating partnership between the health service, industry and academia through the creation of a dedicated digital engineering hub, Cwm Taf Morgannwg University Health Board is improving services and supporting collaborative working within the wider NHS Wales.

The challenge

Throughout the pandemic, Cwm Taf Morgannwg University Health Board (CTMUHB), like many Health Boards across the country, experienced difficulties in sourcing a range of hospital equipment and supplies, from bed management tools and lab sample holders to supporting University colleagues developing Covid testing equipment, as the outbreak placed pressures on the supply industry following increased demand for products.

As well as facing issues obtaining such resources, the pandemic also brought about its own set of challenges as CTMUHB had to adapt and create new tools and procedures to minimise the spread of infection and protect staff and patients. At the same time, the crisis also highlighted shortcomings within existing products and services and the need for innovations to address them.

However, without direct connections to industry, and faced with a number of operational, regulatory and practical obstacles, externally sourcing equipment and skills can be a difficult process for Health Boards and was not a timely enough solution.

The solution

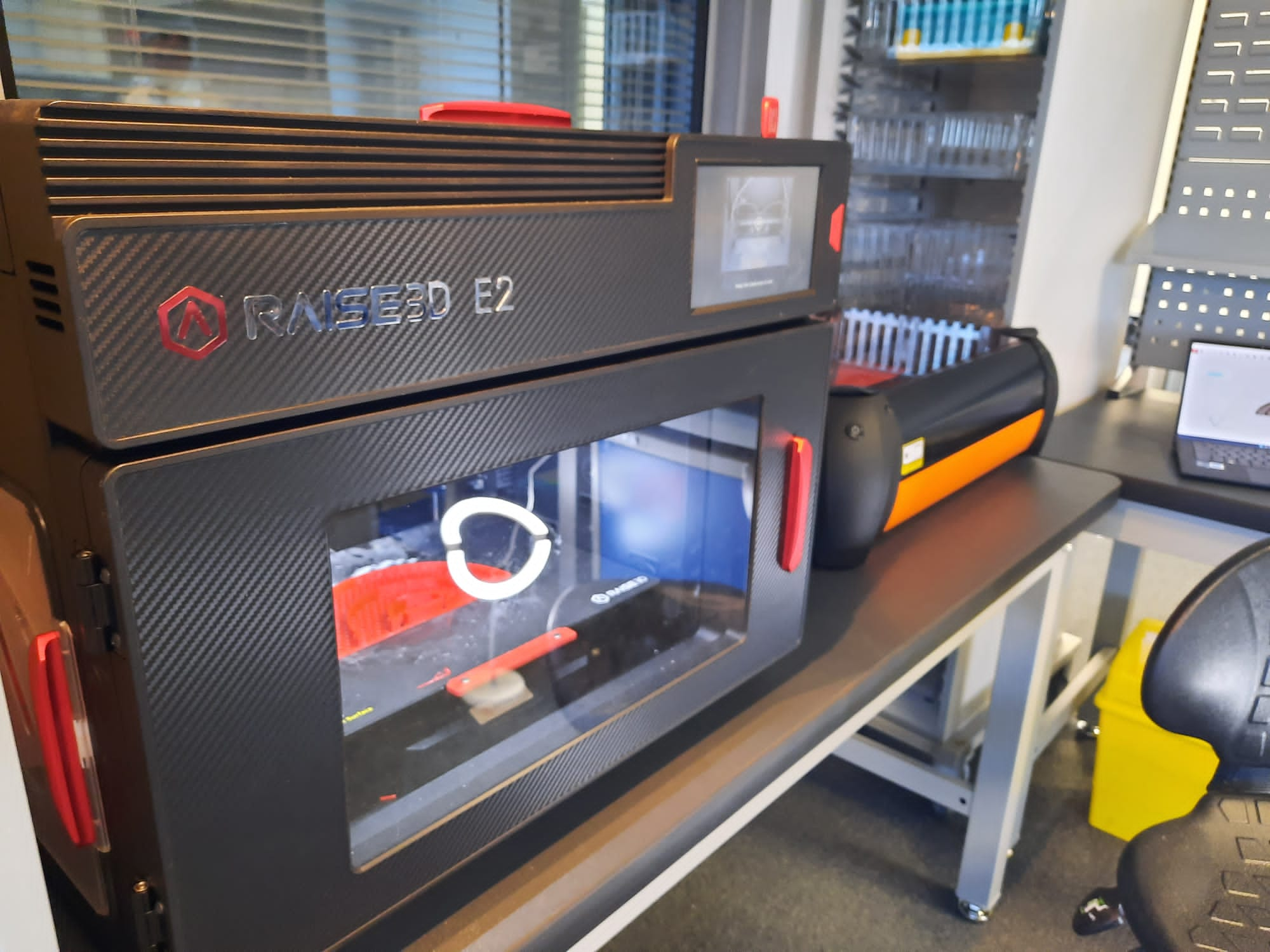

To facilitate the development of innovative ideas and the production of much needed equipment, CTMUHB established the Advanced Digital Physiological Engineering Hub (ADPE) at the Prince Charles Hospital in 2020 with the help of support from Accelerate Wales and the Cardiff Innovation Accelerator at Cardiff University. Repurposing part of the site’s Maxillofacial-Dental laboratory and its 3D printing capabilities, the Hub serves to provide a space to bring together staff, patients, academics and industry partners to collaboratively develop practical solutions to issues.

Together, the team, led by senior chief technologist and dental laboratory manager, Jason Ingham, was able to rapidly prototype and test ideas, using industry know-how to scale up production of the best solutions.

Using the facility’s 3D printers and scanners, including printers loaned to the health board from local schools, a number of items were created including hands-free door opening devices to reduce virus transmission by minimising touch contact, as well as staff badges, used to identify different grades off staff and staff roles in place on lanyards which could no longer be worn in clinical areas due to infection control. The 3D printers also helped to address the global shortage of spare parts for some devices, enabling NHS hospitals to rapidly print their own suitable parts, allowing support equipment to be brought back into service much quicker and saving CTMUHB thousands of pounds in the process.

A key part of the project was a close partnership between CTMUHB and Bridgend-based design and manufacturing company, Innotech Engineering, which is a lead business partner to Accelerate. Andrew Walch, Innotech‘s director, provided his manufacturing expertise to support the Health Board to design and 3D print a range of medical products. These included:

Bed Clips

As hospital beds are moved frequently due to cleaning procedures and patients being transferred between rooms, trailing cables from attached medical machinery can pose a significant trip hazard and lead to damage to the electrical cables if not properly routed. To address this, ADPE Hub designed a bed clip which could alleviate these problems. Product testing has now been completed and hospitals across CTMUHB have placed orders over 2,500 of the products, which are also available across NHS Wales.

Pathology Lab Sample Holder

Sample holders used in the mortuary department were identified as being not fit for purpose given that a typical post-mortem examination consists of two sample tubes and six blood vials, whereas the original holder was only capable of holding two sample tubes, leaving staff in need of further holders for the remainder. To further add to the problem, newer vials purchased by NHS Wales no longer fit the existing vial holders, resulting in vials being inappropriately stored in plastic bags alongside patient paperwork. Through the ADPE Hub, a functional alternative, which was able to store all vials alongside patient documentation, was created. The new design was also substantially cheaper in cost and manufactured locally within South Wales. Working with Innotech, the Hub was able to rapidly convert the prototype into a design suitable for laser cutting from a single sheet of plastic.

Covid LAMP sampling nasal swabs

Academics at the University of South Wales (USW) developed a Covid testing point of care device in response to the pandemic. Dr Emma Hayhurst and Dr Jeroen Nieuwland had previously created a novel molecular detection approach to detect the virus directly but needed rapid prototyping support to develop direct nasal swabs. The ADPE team explored a number of different approaches and materials that have been successfully tested. This was spun out of USW as Llusern Scientific and along with securing joint funding from Welsh Government, Llusern won the MediWales Innovation Start award for their ground-breaking work.

The outcomes

By maximising the benefits of 3D printing, and by facilitating collaborations between an array of different partners across industry, academia and the health service, the ADPE Hub has enabled CTMUHB to rapidly tackle a number of key problem areas. The new Hub has provided state of the art 3D printing and scanning facilities within Cwm Taf Morgannwg, providing a designated working space for industry and academia to support CTMUHB with the development and adoption of novel technologies at pace.

Dr Tom Powell, Head of Innovation at CTMUHB said: “Our ADPE Hub has created community of innovation between clinical engineers, doctors, nurses, academic institutions and businesses. It is supporting the safe development of 3D printing technologies within health care and is enabling hospitals to rapidly print medical devices, parts and anatomical models to meet demand and improve our care.

“The project has also enabled Welsh businesses to work with the NHS and has supported the use of recycled materials, contributing to CTMUHB’s wider sustainability plan.”

Following the success of the project, several of the products developed through the Hub have been adopted by CTMUHB for use across the Health Board, with some products already commercialised and available for purchase directly from Innotech Engineering. As well as bringing operational and patient safety benefits, the Hub has helped to make financial savings for Health Board by reducing manufacturing costs and opening opportunities for commercialisation.

Find out more

For more information on the project, contact Lauren Ware, Project lead and Business Support Manager for Innovation at CTMUHB on Lauren.Ware@wales.nhs.uk

This project is part of the Accelerate programme which is part-funded by the European Regional Development fund, through Welsh Government.